The biological fermentation process requires a reliable system to transfer samples directly from the bioreactor to the analytical equipment while maintaining process sterility. Xierman Technology has launched a fully automatic sampling and biochemical parameter detection - AP-100 online biochemical analyzer, to meet your needs for fully automatic closed-loop feeding in biological cultivation processes. The system can automatically calculate the rate of feed (nutrients such as glucose, glycerol, methanol, glutamine, etc.), accurately control the volume or quality of feed, and import feed data from the process into the data analysis system, thus achieving unmanned biological cultivation process.

Product features

1. Directly connected to the fermentation tank (reactor) in place, capable of high-temperature sterilization, achieving fully automatic sterile sampling;

2. The combination of enzyme electrode technology and selective ion electrode technology results in highly specific substrate recognition, maintaining consistency in data from research and development to amplification of cultivation processes;

3. 24/7 automatic sampling and detection, obtaining complete metabolic parameters of biological culture processes such as glucose, lactate, glutamine, glutamic acid, lysine, ethanol/methanol, xylose, sucrose, glycerol, ammonium ions, sodium ions, potassium ions, calcium ions, etc;

4. Equipped with analog signal output and 485 communication interface, it can be connected to the local automation control system to automatically calculate (perfusion)/feed rate (glucose, glycerol, methanol, glutamine and other nutrients), accurately control feed volume or quality, achieve closed-loop feed control, and achieve "unmanned" biological cultivation process;

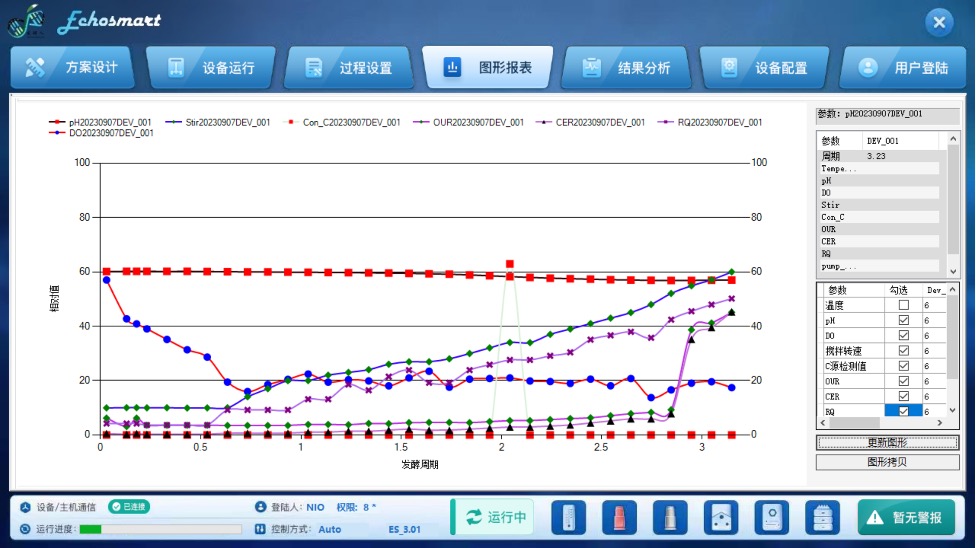

Schematic diagram of glucose closed-loop feeding

The red square represents the curve of glucose concentration throughout the entire fermentation cycle

5. The fully enclosed sterile sampling system, after thousands of verifications, remains safe and reliable;

6. Independently developed ARM control platform, capable of parallel sampling and testing of four reactors simultaneously;

7. We can customize testing items according to customer needs: glucose, xylose, sucrose, lactic acid, glutamic acid, glutamine, lysine, glycerol, ethanol, methanol, ammonium ions, potassium ions, pH, sodium, calcium ions, etc. can be freely combined.

AP-100 online biochemical analyzer

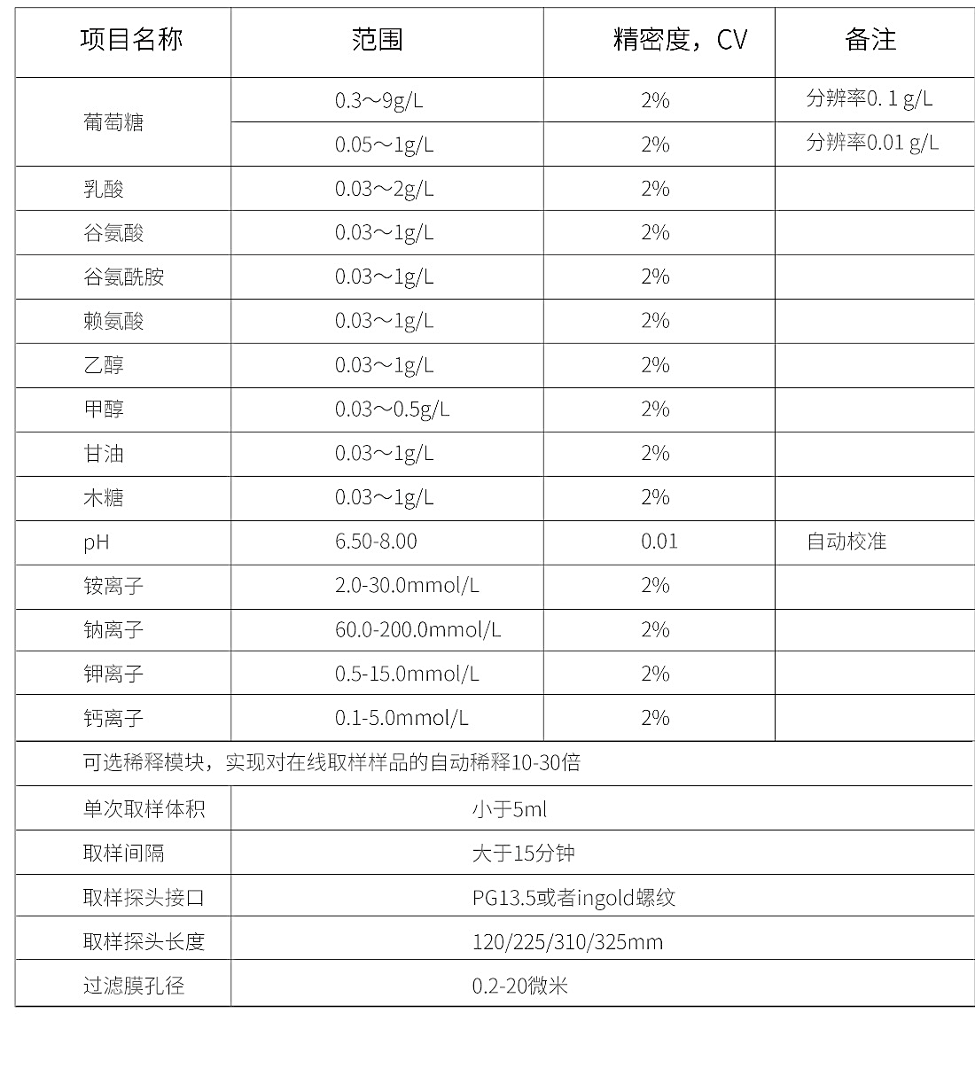

Technical indicators

Application scope

1. Provide reliable and stable process analysis data for the development and production process of recombinant proteins

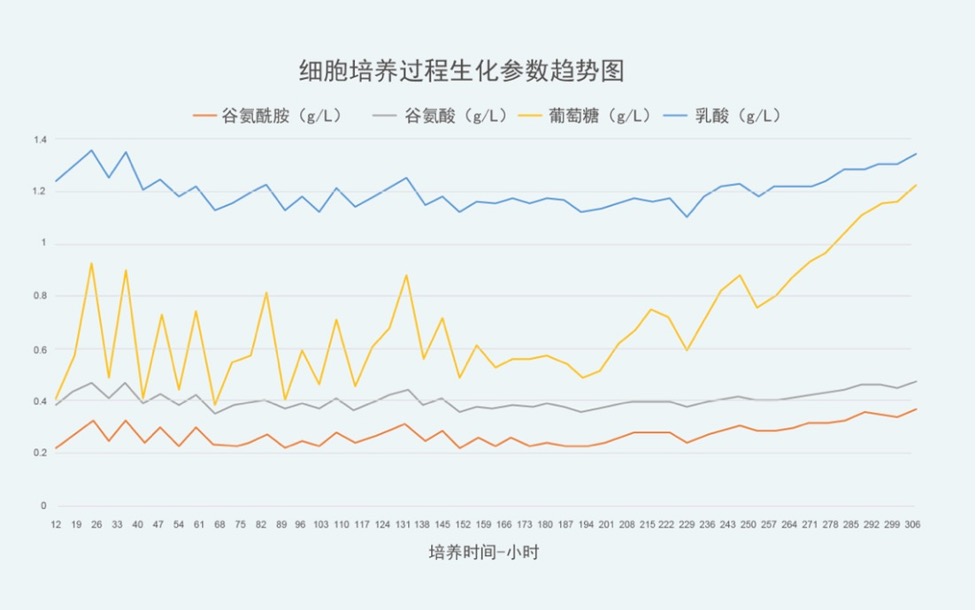

2. Monitoring the consumption of nutrients in the culture medium and the accumulation of metabolic waste during cell culture

3. Detection of glucose metabolism rate in adherent culture, questioning to reflect cell growth status

4. Accurate control of medium replacement timing and reliable guarantee of reproducing experimental results

5. Identify key control points in the process

Application cases

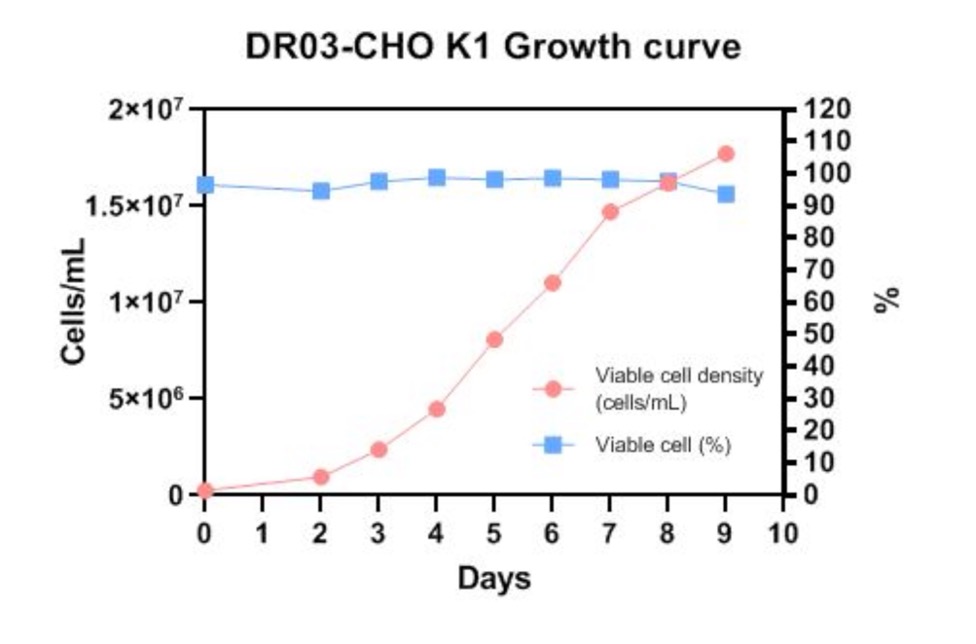

Application of AP-100 in CHO-K1 cell culture process

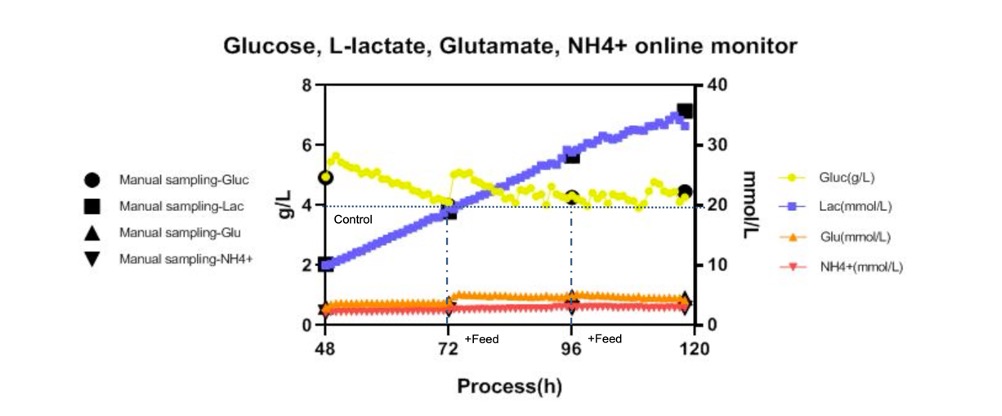

Monitoring nutrients and metabolites plays an important role in the control strategy of cell culture in animal cells. The measurement of glucose and lactate is one of the first steps in this process. The content of glucose and lactate in the culture medium provides information about the biochemical state and life cycle of cells. These results can be used to calculate nutrient rates and real-time control of cultures.

During the CHO-K1 cell culture process, an AP-100 online biochemical analyzer was used, and samples were taken and tested every hour during the early stage of cultivation. In the middle and later stages of cultivation, sampling and testing should be conducted every 4 hours, and the glucose concentration should be controlled at 4g/L for feeding. Other cultivation conditions should be carried out according to normal process parameters.

Tel: 021-3103 8705 /021-3103 7467

Fax: 021-3420 8069

Email: info@yuanmai-bio.com

Add: Floor 2, 199 Hufa Road, Fengxian District, Shanghai, 201415